Our Services

Our technology services deliver efficient solutions tailored to your unique business needs, driving innovation and scalability. With a commitment to excellence, our expert team ensures seamless integration and optimal performance for sustainable growth.

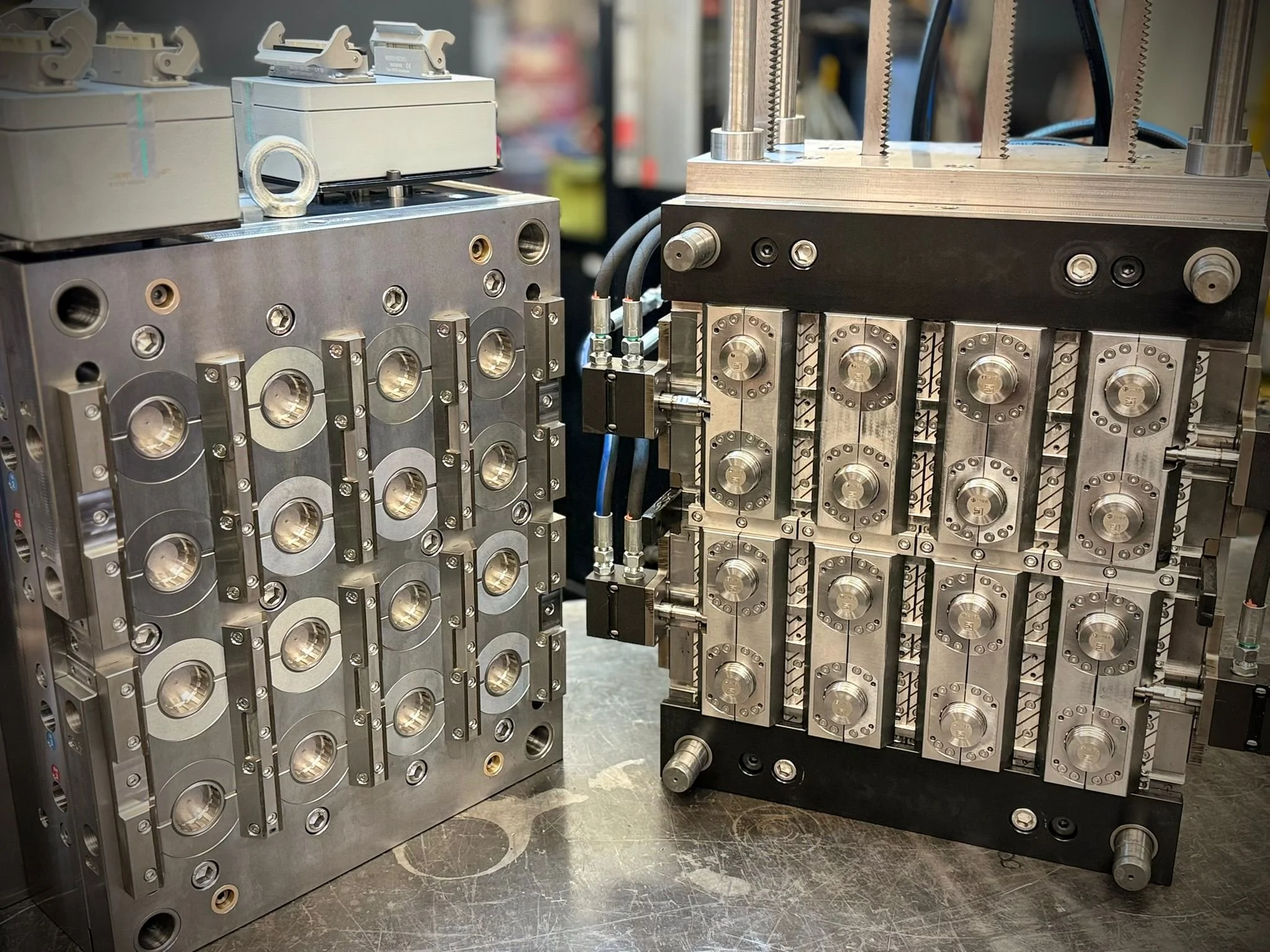

New Tooling Projects

Toolmakers Ltd specialises in new injection mould tooling projects, supporting customers from early pilot and prototype tools through to full production moulds and complete suites of tooling. With extensive experience in caps, closures, packaging, and consumer products, we work closely with our customers from the very beginning — helping refine designs, optimise tooling layouts, and ensure every tool is built for performance, longevity, and repeatability.

Whether the requirement is a single pilot tool or a high-output, fast-cycling production mould, our approach remains the same: precision engineering, practical design, and attention to detail. By combining in-house CNC machining, wire erosion, spark erosion, and laser welding, we deliver tooling that performs reliably in production environments, with a strong focus on quality, consistency, and ease of maintenance throughout the tool’s life.

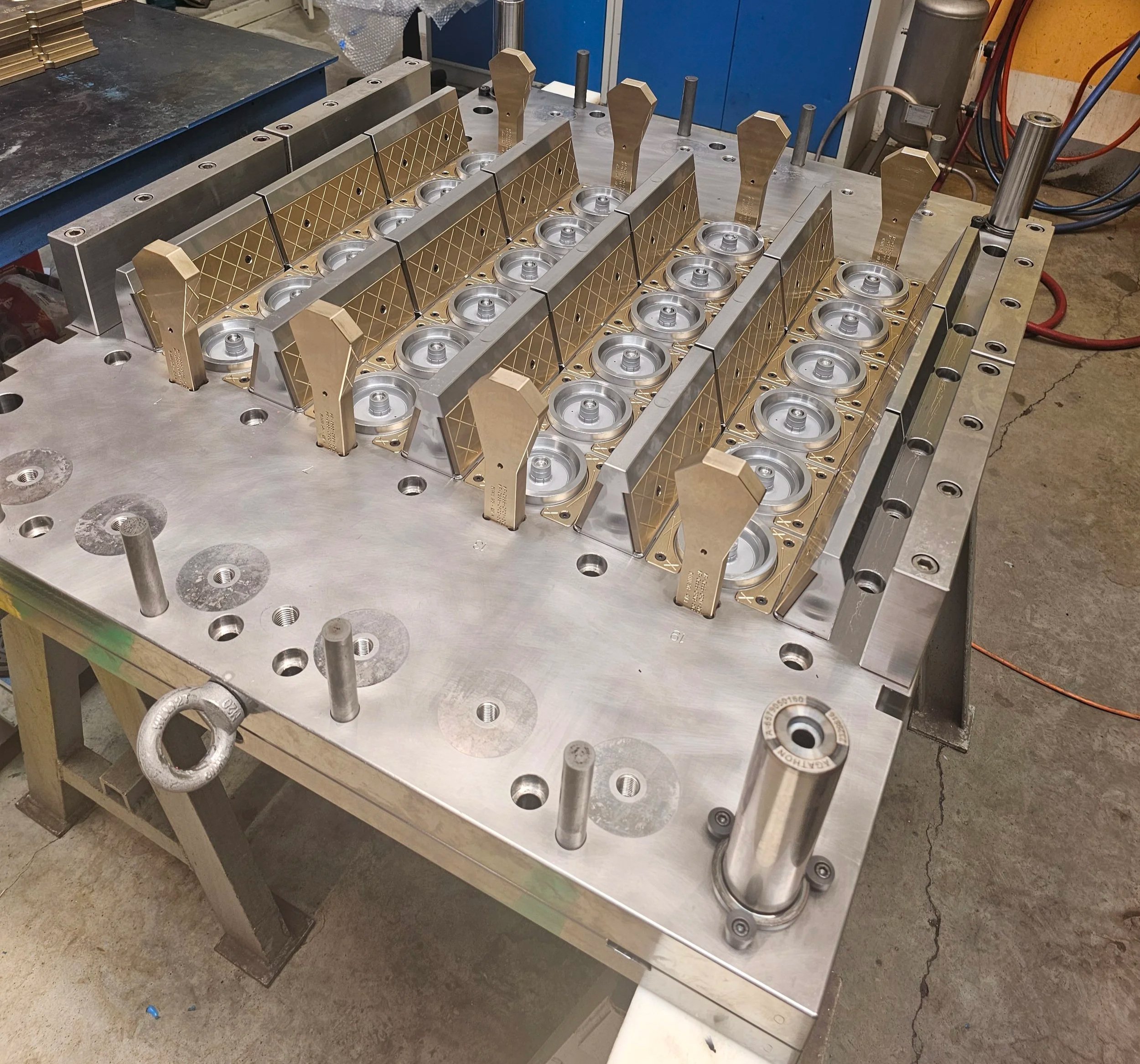

We provide a comprehensive tooling service and repair capability, supporting everything from pilot tools through to high-volume, fast-cycling production moulds. Our in-house expertise allows us to respond quickly to breakdowns, wear issues, and performance concerns, helping minimise downtime and keep production running.

With CNC machining, wire erosion, spark erosion, laser welding, and stock of common tool steels on site, we are able to carry out repairs, modifications, insert replacements, and refurbishments efficiently and accurately — even on hardened tooling. We also support tool re-qualification and life-extension work, restoring tools that have produced millions or even billions of parts back to a reliable production standard. Our focus is always on fast reaction, precision repair, and long-term performance.

Tooling Service, Repair & Refurbishment

Alongside toolmaking, Toolmakers Ltd offers precision CNC production machining for batch work, repeat components, one-off parts, and concept development. Our production work benefits directly from our toolmaking background — meaning parts are machined with exceptional attention to detail, high-quality finishes, and tight control over accuracy and consistency.

We support customers with fast turnaround production, overflow machining capacity, and short-notice requirements, working flexible hours where needed to meet lead times. From small batches to ongoing repeat work, we deliver components that not only meet functional requirements but also reflect the quality and precision expected from a specialist toolroom. This makes us a trusted partner for customers who value both speed and workmanship.